Best way to keep track of inventory for small business – In the realm of small business success, inventory management stands as a cornerstone. Embark on a journey of knowledge as we delve into the best practices, strategies, and tools that will transform your inventory tracking into a streamlined and efficient operation.

From manual methods to cutting-edge software solutions, we’ll guide you through the intricacies of inventory management, empowering you to optimize your stock levels, minimize discrepancies, and maximize profitability.

Inventory Management Methods

Inventory management is crucial for businesses to maintain accurate records of their stock, avoid overstocking or stockouts, and optimize their operations. Various methods are available for inventory tracking, ranging from manual to automated systems, each with its advantages and disadvantages.

Manual Methods

- Pen and Paper: Traditional method involving handwritten records in notebooks or ledgers, which can be prone to errors and time-consuming for large inventories.

- Spreadsheets: Digital version of pen and paper method using software like Microsoft Excel, offering better organization and data manipulation capabilities, but still susceptible to human errors.

- Physical Tags: Attaching tags to inventory items with information like quantity, description, and location, providing a visual representation of inventory levels but limited in data tracking capabilities.

Automated Methods

- Barcode Scanners: Devices that read barcodes attached to inventory items, automating data entry and reducing errors. Can be integrated with inventory management software for real-time tracking.

- RFID Tags: Radio Frequency Identification tags that use radio waves to transmit data, allowing for contactless tracking of inventory items and providing more detailed information than barcodes.

- Inventory Management Software: Comprehensive software solutions that automate inventory tracking, provide real-time updates, generate reports, and facilitate integration with other business systems.

| Method | Advantages | Disadvantages |

|---|---|---|

| Manual | – Low initial cost – Easy to implement – No specialized equipment required |

– Prone to errors – Time-consuming – Limited data tracking capabilities |

| Automated | – Improved accuracy – Reduced labor costs – Real-time tracking – Comprehensive data analysis |

– Higher initial investment – Requires specialized equipment – May require training |

Inventory Tracking Best Practices: Best Way To Keep Track Of Inventory For Small Business

Implementing effective inventory tracking practices is crucial for maintaining accurate inventory records and minimizing discrepancies. Regular inventory counts, coupled with appropriate counting methods and techniques, can significantly improve inventory management.

Importance of Regular Inventory Counts

- Ensure inventory accuracy and prevent overstocking or stockouts.

- Identify and address discrepancies between physical inventory and records.

- Detect shrinkage due to theft, damage, or misplacement.

- Monitor inventory turnover and identify slow-moving items.

- Plan for future inventory needs and optimize purchasing decisions.

Methods for Conducting Inventory Counts

Cycle Counting

Involves counting a small portion of inventory on a regular schedule, rather than counting the entire inventory at once. This method reduces the risk of errors and ensures more frequent monitoring.

Spot Checks

Randomly selecting and counting specific items to verify their accuracy. This method is less comprehensive than cycle counting but can be useful for identifying potential issues.

Techniques for Minimizing Inventory Discrepancies

- Use barcode scanners or RFID technology for accurate data capture.

- Implement a perpetual inventory system to track inventory in real-time.

- Train staff on proper inventory counting procedures.

- Conduct regular audits to verify inventory accuracy.

- Use inventory management software to automate inventory tracking and minimize errors.

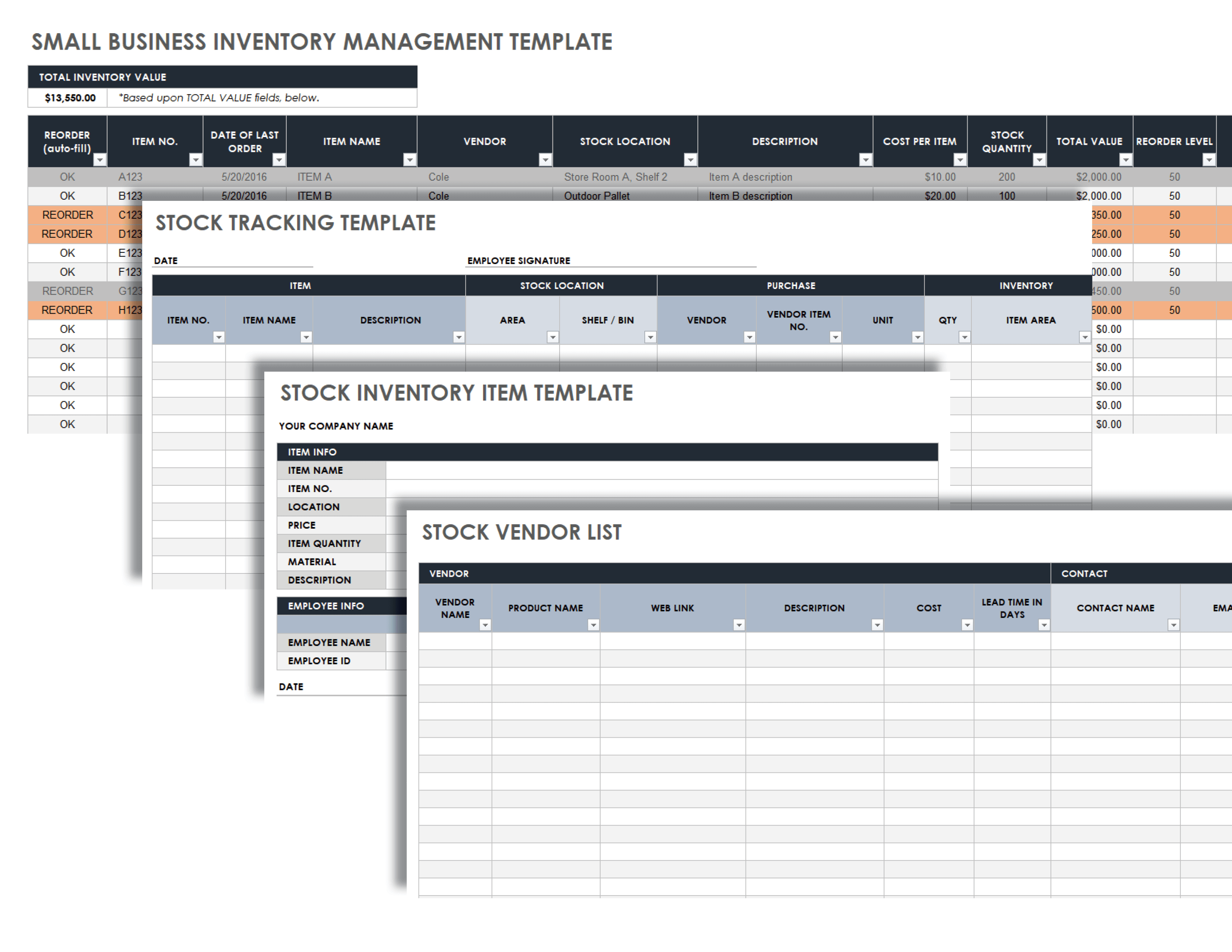

Inventory Management Software

Inventory management software can help small businesses streamline their inventory processes, improve accuracy, and save time and money. When choosing inventory management software, there are several key features to look for, including:

Features to Look for in Inventory Management Software

- Product tracking: The software should allow you to track inventory levels for each product, including stock on hand, on order, and in transit.

- Inventory valuation: The software should be able to calculate the value of your inventory using different costing methods, such as FIFO, LIFO, and average cost.

- Reorder point management: The software should allow you to set reorder points for each product, so that you can be notified when inventory levels are low.

- Purchase order management: The software should allow you to create and manage purchase orders, track the status of orders, and receive inventory.

- Reporting: The software should provide a variety of reports, such as inventory reports, sales reports, and purchase reports.

Types of Inventory Management Software

There are three main types of inventory management software:

- Cloud-based: Cloud-based inventory management software is hosted on a remote server, so you can access it from anywhere with an internet connection. This type of software is typically more affordable than on-premises software, and it is easier to set up and maintain.

- On-premises: On-premises inventory management software is installed on your own server. This type of software is typically more expensive than cloud-based software, but it gives you more control over your data.

- Open source: Open source inventory management software is free to download and use. This type of software is typically less feature-rich than commercial software, but it can be a good option for small businesses on a budget.

Choosing the Right Inventory Management Software for Your Small Business

When choosing inventory management software for your small business, it is important to consider the following factors:

- The size of your business: The size of your business will determine the features and functionality you need in inventory management software.

- The type of products you sell: The type of products you sell will also affect the features you need in inventory management software. For example, if you sell perishable goods, you will need software that can track expiration dates.

- Your budget: The cost of inventory management software can vary significantly. It is important to set a budget before you start shopping for software.

Inventory Optimization Techniques

![]()

Inventory optimization is the process of determining the optimal levels of inventory to hold to meet customer demand while minimizing costs. It involves finding the right balance between holding too much inventory, which can lead to waste and storage costs, and holding too little inventory, which can result in stockouts and lost sales.

There are several different inventory optimization techniques that businesses can use, including:

Just-in-Time Inventory

Just-in-time (JIT) inventory is a method of inventory management that seeks to minimize inventory levels by only ordering inventory when it is needed. This can help businesses reduce storage costs and the risk of obsolescence. JIT inventory is often used in conjunction with lean manufacturing principles.

Safety Stock

Safety stock is an additional amount of inventory that businesses hold above their normal inventory levels to buffer against unexpected demand or supply disruptions. Safety stock can help businesses avoid stockouts and lost sales, but it also increases storage costs.

Reorder Points, Best way to keep track of inventory for small business

Reorder points are the inventory levels at which businesses place new orders. Reorder points are typically set based on historical demand data and the lead time for new orders. Setting the reorder point too high can lead to excess inventory, while setting it too low can lead to stockouts.

Inventory optimization can help businesses improve efficiency and reduce costs by:

- Reducing inventory levels

- Minimizing storage costs

- Reducing the risk of obsolescence

- Avoiding stockouts and lost sales

Inventory Forecasting

Inventory forecasting is a crucial aspect of inventory management that helps businesses predict future demand and optimize their inventory levels. By accurately forecasting demand, businesses can avoid stockouts, reduce excess inventory, and improve their overall operational efficiency.

There are several different inventory forecasting methods, each with its own advantages and disadvantages. Some of the most common methods include:

- Historical data analysis: This method uses historical sales data to forecast future demand. It is a relatively simple and straightforward method, but it can be less accurate if there are significant changes in demand patterns.

- Trend analysis: This method uses trend lines to forecast future demand. It is useful for identifying long-term trends in demand, but it can be less accurate for short-term fluctuations.

- Demand forecasting: This method uses a variety of factors, such as economic indicators, market research, and customer surveys, to forecast future demand. It is a more complex method than historical data analysis or trend analysis, but it can be more accurate.

When forecasting inventory, it is important to consider a number of factors, such as:

- Seasonality: Demand for many products varies depending on the time of year. It is important to consider seasonality when forecasting inventory to avoid stockouts during peak demand periods.

- Lead time: The lead time is the amount of time it takes to receive inventory from suppliers. It is important to consider lead time when forecasting inventory to avoid running out of stock while waiting for new inventory to arrive.

- Safety stock: Safety stock is a buffer of inventory that is kept on hand to protect against unexpected increases in demand or delays in delivery. It is important to determine the appropriate level of safety stock to avoid both stockouts and excess inventory.

Wrap-Up

As you implement the insights gained from this comprehensive guide, your small business will be equipped to navigate the challenges of inventory management with confidence. Embrace the power of efficient inventory tracking and unlock the path to enhanced profitability and operational excellence.

FAQ Guide

What are the key benefits of inventory management software?

Inventory management software streamlines inventory tracking, reduces errors, optimizes stock levels, and provides real-time insights into your inventory status.

How can I choose the right inventory management software for my small business?

Consider factors such as your business size, industry, inventory volume, and budget when selecting inventory management software.

What are some effective inventory optimization techniques?

Just-in-time inventory, safety stock, and reorder points are proven inventory optimization techniques that can help you minimize waste and improve efficiency.